INFRASTRUCTURE

Because Great Quality Asks For Great Technology

OUR INFRASTRUCTURE

Equipment and Technology

At Ananta Metal Recycling, we take immense pride in our state-of-the-art infrastructure, which plays a pivotal role in our journey of recycling and redefining aluminium.

From the initial processing stages to the final product, our facilities are designed to ensure the best in class recycled aluminium output. Our facilities are designed to handle the complex process of aluminium recycling efficiently, while also adhering to the highest standards of environmental and safety regulations.

COMPONENTS

Our essential components

Below are the essential components of our infrastructure: Here's a deep dive into the equipment and facilities that empower our operations:

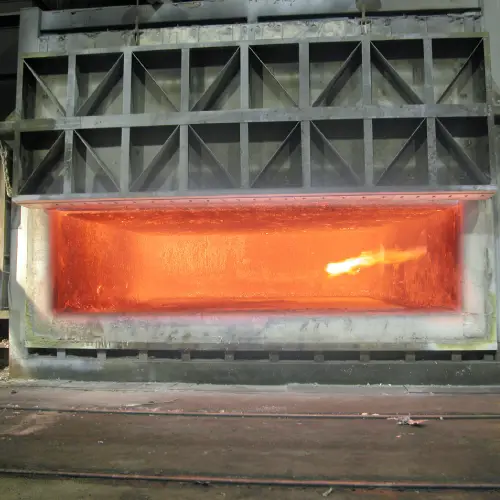

Machinery and Furnaces:

- Bailing Machines

- Tumbling Machine

- Tilting Rotary Furnace

- Rotary Furnace

- Skelner Furnaces

- Crucible Furnace

Space and Layout:

- Area of 218000sq.ft: Our expansive facility spread across 218000 square feet, is meticulously designed to house our advanced machinery and ensure smooth operations.

Weighing and Measurement:

- Multiple Weighing Scales

- In House Weigh Bridge (100MT)

- Crane Scale

Shredding and Material Processing:

- Twin-Shaft Shredders

- Cable Cutters

- Overband Magnetic Separator

- Double Drum Magnetic Separator

- Magnetic Conveyor

- Continuous Bailing Machine

- Briquetting Machine

Material Handling:

- Forklifts

- Hydra / Crane

- Loaders

Each piece of equipment and facility component stands as a testament to our dedication towards setting high standards in the aluminium recycling industry.

At Ananta Metal Recycling, we believe in combining technological prowess with sustainable practices, ensuring a brighter future for our planet and generations to come.

Total Capacity - 20000 mt +

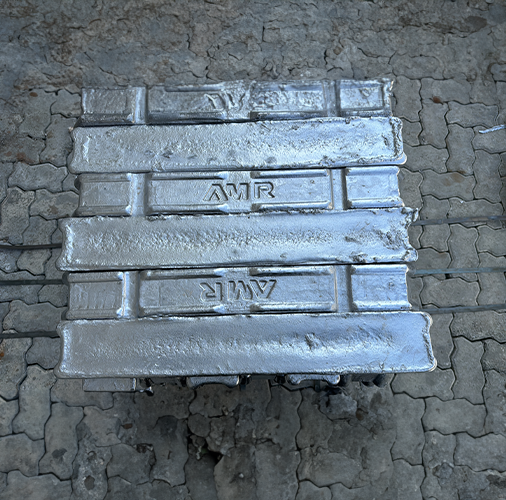

Our state-of-the-art facility boasts an impressive production capability, churning out high-quality aluminum ingots, bars, shots, and alloys with unparalleled efficiency. In a given timeframe, our manufacturing prowess enables us to achieve a substantial total capacity, meeting the demands of diverse industries. Whether it's precision-engineered ingots, versatile bars, or customized alloys, our facility ensures a seamless production process, maintaining rigorous quality standards. Our commitment to excellence allows us to consistently deliver on large-scale orders, making us a reliable partner for clients seeking top-tier aluminum products. With cutting-edge technology and a dedicated workforce, we take pride in our ability to meet and exceed production expectations.