OUR PRODUCTS

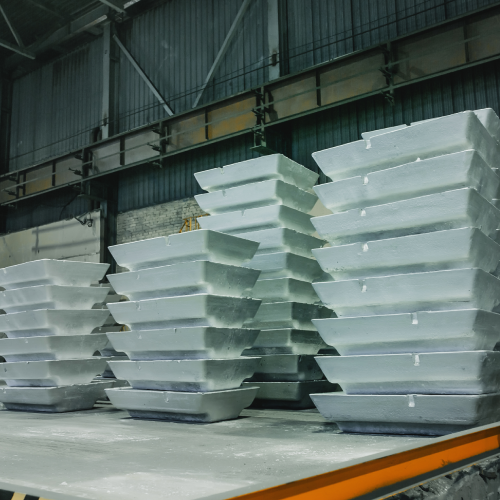

Aluminium Sow Ingot

| Grade | Weight |

|---|---|

| 98.5% Min | 250 kgs |

| 98% Min | 500 kgs |

| 97.5% Min | |

| 97% Min | |

| 96% Max |

We Manufacture the Following Grades:

| Grade | Mg | Si | Fe | Cu | Zn | Mn | Others | Al |

|---|---|---|---|---|---|---|---|---|

| 98.5% Min | 0.20% Max | 0.60% Max | 0.40% Max | 0.15% Max | 0.20% Max | 0.15% Max | 0.10% Max | 98.5% Min |

| 98% Min | 0.20% Max | 0.30% Max | 0.40% Max | 0.20% Max | 0.15% Max | 0.50% Max | 0.10% Max | 98% Min |

| 97.5% Min | 0.25% Max | 0.30% Max | 0.60% Max | 0.25% Max | 0.25% Max | 0.80% Max | 0.15% Max | 97.5% Min |

| 97% Min | 0.25% Max | 0.40% Max | 0.60% Max | 0.40% Max | 0.50% Max | 0.80% Max | 0.20% Max | 97% Min |

| 96% Max | 0.30% Max | 1% Max | 1% Max | 0.60% Max | 0.60% Max | 1% Max | 0.30% Max | 96% Min |

Key Features:

Sustainability:

Sustainability:

Employing secondary aluminum sow ingots reduces waste and environmental impact by using recycled materials.

Versatility:

Versatility:

These ingots can be melted and alloyed for specific industry needs, offering manufacturing flexibility.

Energy Efficiency:

Energy Efficiency:

Producing secondary aluminum sow ingots needs considerably less energy than primary aluminum.

Cost-Effectiveness:

Cost-Effectiveness:

Using recycled material often leads to more economical production compared to new materials.

Aluminum secondary sow ingots, produced from recycled aluminum scrap, play a crucial role in numerous industries due to their cost-effectiveness, eco-friendliness, and adaptability in different alloy compositions. The production process involves gathering and melting scrap aluminum, refining it to purge impurities, and casting it into sow ingot forms for reuse. This method promotes a circular economy and consumes less energy than primary aluminum production from bauxite ore. Using secondary aluminum sow ingots, industries can maintain high-quality material utilization without sacrificing material properties. We blend primary aluminum (remelt ingot or liquid metal) with scrap to forge sow ingots for wrought aluminum production, selecting a variety of scrap to minimize costs.

Applications for Aluminum Secondary Sow Ingots

→ Deoxidation in Steel Industry:

Process: As a deoxidizer in steel making, reacting with oxygen in molten steel to form aluminum oxide, thus reducing steel's oxygen content.

Benefits: Enhances steel’s structural integrity, preventing gas pores and improving toughness and durability.

Forms: Melted secondary sow ingots are introduced in steelmaking for deoxidation.

→ Automobile Industry:

Used in making engine parts, panels, and wheels due to their lightweight and durability.

→ Packaging:

Recycled aluminum creates cans, foils, and other packaging, promoting sustainability and recyclability.

→ Construction:

Employed for window frames, panels, and roofing due to its corrosion resistance and strength.

→ Aerospace:

Ideal for various components because of its light weight and high strength.

→ Electrical:

Used in wiring and electrical components manufacturing for its excellent conductivity.

→ Consumer Goods:

Used in household items, gadgets, and appliances, benefiting from its malleability and corrosion resistance.

Production Process

Collection

Sorting and Cleaning

Melting

Refining

Casting

Connect with us

to explore various options

on recycled aluminium

Storage and Handling

Store aluminum secondary sow ingots in a clean, dry place to avoid contamination and corrosion. Use safety gear like gloves, goggles, and protective clothing for handling. Secure stacking and storage reduce risks related to material displacement or accidental falls.

Conclusion

Using aluminum secondary sow ingots is a practical, sustainable strategy, promoting recycling and efficient material use across industries. With the resource and energy intensity of primary aluminum production, secondary aluminum is an economically and environmentally sound alternative, meeting industry demands while conserving resources.