OUR PRODUCTS

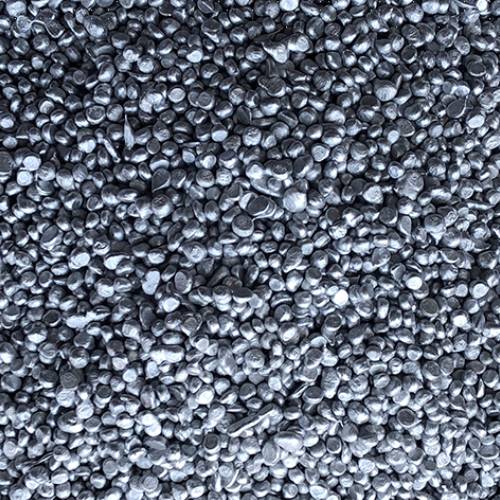

Aluminium Shots

| Spec | Size |

|---|---|

| Al : 96 %min , 97% min | 5-15 mm |

Key Features:

Purity:

Purity:

Aluminum shots typically have high levels of purity, ensuring consistent performance and minimal impurities.

Uniformity:

Uniformity:

Their consistent size and shape ensure predictable behavior in various applications.

Durability:

Durability:

They resist wear and tear, providing longevity in usage.

Thermal Conductivity:

Thermal Conductivity:

Aluminum is known for its excellent thermal properties, making aluminum shots ideal for applications requiring rapid heating or cooling.

Aluminum shots, small spheres or granules made from high-grade aluminum, serve a variety of industries due to their durability, malleability, and excellent thermal conductivity. Aluminum shot confined by exhausting fluid aluminum into water isn't alluring by excellence of its coarse size and minimization of structure, along these lines giving moderate and divided reactions.

The ideal type of aluminum for these responses is known as grained aluminum, and is delivered by breaking up the metal precisely similarly as it is going from the fluid to the strong state. Likewise, these are fabricated by melting of primary or secondary aluminum and blown into air or vacuum, or are thrown in sand and sieved off. Different techniques incorporate throwing of liquid aluminum in water.

Applications for Aluminum Shots:

→ Deoxidation in Steel Manufacturing:

One of the primary uses of aluminum shots is in the steel manufacturing process. Steel can contain dissolved oxygen which, if not removed, can cause brittleness and other undesirable properties in the final product. Aluminum, when added to molten steel, reacts with this dissolved oxygen to form aluminum oxide, which then floats to the surface of the molten steel and is removed. This process is known as deoxidation. Aluminum shots provide a convenient form of aluminum to add to the steel, as they can be easily dispersed in the molten metal.

→ Metal Production:

Aluminum shots can also be used in some metallurgical processes, serving as a raw material.

→ Cosmetic or Decorative Applications:

In some contexts, the shiny appearance of aluminum shots might be desired for decorative or craft purposes.

→ Research & Laboratory:

In specific experimental setups or processes, aluminum shots can be used due to their consistent size, shape, and composition.

→ Blast Cleaning:

Similar to steel shots or glass beads, aluminum shots can be used in shot blasting processes to clean surfaces. However, since aluminum is softer than steel, its use is typically restricted to cleaning more delicate surfaces or where there's a need to prevent contamination with ferrous materials.

→ Weighting and Counterbalance:

Due to their small, consistent size and weight, aluminum shots might be used in certain specialized applications where precise weighting or counterbalance is needed.

Connect with us

to explore various options

on recycled aluminium

Storage and Handling

Aluminum shots should be stored in a cool, dry place, away from excessive moisture and contaminants.

When handling, it's essential to wear appropriate safety gear, including gloves and eye protection, to prevent any injuries.